What is clay?

Clay is a naturally occurring material composed primarily of fine-grained minerals, which show plasticity through a variable range of water content, and which can be hardened when dried and/or fired. Clay deposits are mostly composed of clay minerals (phyllosilicate minerals), minerals which impart plasticity and harden when fired and/or dried, and variable amounts of water trapped in the mineral structure by polar attraction.

Definition

Clays are distinguished from other fine-grained soils by various differences in composition. Silts, which are fine-grained soils which do not include clay minerals, tend to have larger particle sizes than clays, but there is some overlap in both particle size and other physical properties, and there are many naturally occurring deposits which include both silts and clays. The distinction between silt and clay varies by discipline. Geologists and soil scientists usually consider the separation to occur at a particle size of 2 µm (clays being finer than silts), sedimentologists often use 4-5 μm, and colloid chemists use 1 μm.

Clay minerals are hydrous aluminium phyllosilicates, sometimes with variable amounts of iron, magnesium, alkali metals, alkaline earths and other cations. Clays have structures similar to the micas and therefore form flat hexagonal sheets. Clay minerals are common weathering products (including weathering of feldspar) and low temperature hydrothermal alteration products. Clay minerals are very common in fine grained sedimentary rocks such as shale, mudstone and siltstone and in fine grained metamorphic slate and phyllite.

Clay minerals include the following groups:

• Kaolin group which includes the minerals kaolinite, dickite, halloysite and nacrite. The “kaolins” are also known as primary clays.

• Smectite group which includes dioctahedral smectites such as montmorillonite and nontronite and trioctahedral smectites for example saponite.

• Illite group which includes the clay-micas. Illite is the only common mineral.

• Chlorite group includes a wide variety of similar minerals with considerable chemical variation.

These minerals are typically formed over long periods of time by the gradual chemical weathering of rocks by low concentrations of carbonic acid and other diluted solvents. These solvents (usually acidic) migrate through the weathering rock after leaching through upper weathered layers. In addition to the weathering process, some clay minerals are formed by hydrothermal activity. Clay deposits may be formed in place as residual deposits, but thick deposits usually are formed as the result of a secondary sedimentary deposition process after they have been eroded and transported from their original location of formation. Clay deposits are typically associated with very low energy depositional environments such as large lake and marine deposits.

Historical and modern uses

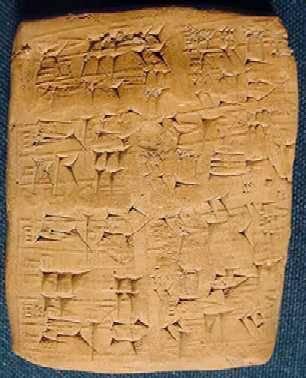

Clay tablets were used as the first writing medium, inscribed with cuneiform script through the use of a blunt reed called a stylus. Clays sintered in fire were the first form of ceramic. Bricks, tiles, cooking pots, art objects, dishware and even musical instruments such as the ocarina can all be shaped from clay before being fired. Clay is also used in many industrial processes, such as paper making, cement production and chemical filtering. Clay is also often used in the manufacture of pipes for smoking tobacco.

Clay, being relatively impermeable to water, is also used where natural seals are

needed, such as in the cores of dams, or as a barrier in landfills against toxic seepage ('lining' the landfill, preferably in combination with geotextiles).

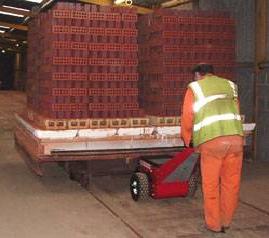

Perhaps the best use of clay and the one that we are most aware of is for the manufacture of bricks, tiles and glassware of which Portugal has such a strong and long tradition. The building industry relies heavily on red clays for

supply of the raw materials for businesses, houses and apartment buildings.

The fundamentals of brick manufacturing have not changed over time. However, technological advancements have made contemporary brick plants substantially more efficient and have improved the overall quality of the products.

The manufacturing process has six general phases:

1) mining and storage of raw materials - Surface clays, shales and some fire clays are mined in open pits with power equipment. Then the clay or shale mixtures are transported to plant storage areas.

2) preparing raw materials - To break up large clay lumps and stones, the material is processed through size-reduction machines before mixing the raw material. Usually the material is processed through inclined vibrating screens to control particle size.

3) forming the brick - Tempering, the first step in the forming process, produces a homogeneous, plastic clay mass. Usually, this is achieved by adding water to the clay in a pug mill (see Photo 2), a mixing chamber with one or more revolving shafts with blade extensions. After pugging, the plastic clay mass is ready for forming. There are three principal processes for forming brick: stiff-mud, soft-mud and dry-press.

Stiff-Mud Process - In the stiff-mud or extrusion process (see Photo 3), water in the range of 10 to 15 percent is mixed into the clay to produce plasticity. After pugging, the tempered clay goes through a deairing chamber that maintains a vacuum of 15 to 29 in. (375 to 725 mm) of mercury. De-airing removes air holes and bubbles, giving the clay increased workability and plasticity, resulting in greater strength.

Next, the clay is extruded through a die to produce a column of clay. As the clay column leaves the die, textures or surface coatings may be applied. An automatic cutter then slices through the clay column to create the individual brick. Cutter spacings and die sizes must be carefully calculated to compensate for normal shrinkage that occurs during drying and firing. About 90% of brick in the United States are produced by the extrusion process.

Soft-Mud Process - The soft-mud or molded process is particularly suitable for clays containing too much water to be extruded by the stiff-mud process. Clays are mixed to contain 20 to 30 percent water and then formed into brick in molds. To prevent clay from sticking, the molds are lubricated with either sand or water to produce “sand-struck” or “water-struck” brick. Brick may be produced in this manner by machine or by hand.

Dry-Press Process - This process is particularly suited to clays of very low plasticity. Clay is mixed with a minimal amount of water (up to 10%), then pressed into steel molds under pressures from 3.4 to 10.3 MPa by hydraulic or compressed air rams.

4) drying - Wet brick from molding or cutting machines contain 7 to 30% moisture, depending upon the forming method. Before the firing process begins, most of this water is evaporated in dryer chambers at temperatures ranging from about 38 ºC to 204 ºC. The extent of drying time, which varies with different clays, usually is between 24 to 48 hours. Although heat may be generated specifically for dryer chambers, it usually is supplied from the exhaust heat of kilns to maximize thermal efficiency. In all cases, heat and humidity must be carefully regulated to avoid cracking in the brick.

5)

5) firing and cooling - Brick are fired between 10 and 40 hours, depending upon kiln type and other variables. There are several types of kilns used by manufacturers. The most common type is a tunnel kiln. In a tunnel kiln, brick are loaded onto kiln cars, which pass through various temperature zones as they travel through the tunnel. The heat conditions in each zone are carefully controlled, and the kiln is continuously operated.

Firing may be divided into five general stages: 1) final drying (evaporating free water); 2) Dehydration; 3) oxidation; 4) vitrification; and 5) flashing or reduction firing.

All except flashing are associated with rising temperatures in the kiln. Although the actual temperatures will differ with clay or shale, final drying takes place at temperatures up to about 204 ºC, dehydration from about 149 ºC to 982 ºC, oxidation from 538 ºC to 982 ºC and vitrification from 871 ºC to 1316 ºC,

and 6) de-hacking and storing finished products - De-hacking is the process of unloading a kiln or kiln car after the brick have cooled.

For the manufacturing process to be efficient, the raw material (clay) must be close to the manufacturing centre. Ideally this radius should be in the order of 2 to 3 km but as transport methods and routes have improved, it can now be up to 60 km. In certain cases, depending on the quality of the clay, some “special clays” (kaolins for example) are even exported abroad.

In Portugal transformation companies have first set up their factories (kilns) in suitable places and secondly focused their concerns on the supply of raw materials. Because of this there are many factories that are now abandoned because the transport costs, which can be as high as 60% of production costs, have exceeded profit margins. It is therefore a common site to see the smokeless tall chimneys in the Santarém, Benavente, Tomar and Torres Vedras areas. These areas are known producers of “common clays” or “red clays” that are used for the ceramic industry but many of the factories are well outside the areas of influence of these towns.

Geologically the clays occur in discordant Pliocene age sediments over Miocene age sediments in Santarém, Benavente and Tomar and in Upper Jurassic sediments in the Torres Vedras area.

The cache takes you to Labrugeira, 16 km W of Torres Vedras, location of an abandoned brick and tile manufacturing factory (kiln) where many of the features described in the above text may still be viewed. You can observe the location where each manufacturing stage took place and observe the kilns.

You are asked to pay special attention to the tunnel kilns where the geological raw materials were converted into bricks and tiles.

The cache:

To validate your log on this earthcache, you need to perform two tasks.

On the given coordinate, search for tunel number 17 and determine its width and height. Send me these values by email and wait for my answer before posting your log. Please do not post photos of the tunel 17 in your log.

Besides those values, you optionally take a picture of yourself near the tile panel at N39º 07.265' W09º 03.866' and include this photo in your log.

EarthCaching: Observe, learn, enjoy and be safe!

Sources:

http://en.wikipedia.org/wiki/Clay_mineral

http://en.wikipedia.org/wiki/Clay

Moreira, JCB, 1997. Matérias Primas Minerais não Metálicas. Situação actual e Perspectivas. Bol. Minas, Lisboa, 34(4), p.379-432.

The most exciting way to learn about the Earth and its processes is to get into the outdoors and experience it first-hand. Visiting an Earthcache is a great outdoor activity the whole family can enjoy. An Earthcache is a special place that people can visit to learn about a unique geoscience feature or aspect of our Earth. Earthcaches include a set of educational notes and the details about where to find the location (latitude and longitude). Visitors to Earthcaches can see how our planet has been shaped by geological processes, how we manage the resources and how scientists gather evidence to learn about the Earth. To find out more click HERE.

The most exciting way to learn about the Earth and its processes is to get into the outdoors and experience it first-hand. Visiting an Earthcache is a great outdoor activity the whole family can enjoy. An Earthcache is a special place that people can visit to learn about a unique geoscience feature or aspect of our Earth. Earthcaches include a set of educational notes and the details about where to find the location (latitude and longitude). Visitors to Earthcaches can see how our planet has been shaped by geological processes, how we manage the resources and how scientists gather evidence to learn about the Earth. To find out more click HERE.