Fereirra Mine Stope

About the site:

The small museum is maybe one of the smallest and most unknown to the general public. During the construction of the building in 1986, the contractors discovered an entrance to the tunnel or stope to old mining works three levels below ground. Investigations proved that it had been the site of one of Johannesburg's first sub-surface digging mines. During 1880's the stope was on ground level and was aburied deep below the surface in the past 100 years or so. The Stope was found inside the building perameters of the Standard Bank Head Office and subequently, it was decided to share the site with the general public and turned the stope into a museum. There are NO entrance fees and it is open to the general public 24/7.

To get to the museum: Enter the building at 5 Simmonds and turn left and find the lift opposite the bank in the foyer. (Refer to the first photograph of this listing.) Take the lift and go down and back in time to level -3. Enjoy your visit!

The Simmonds Street site forms part of the area underlain by the Witwatersrand's main conglomerate formation or gold reef. This gold quartzite traverses the area in an east-west direction and dips southwards at a steep angle of about 80degrees. The northern rock walls forms part of the northern rim of the Witwatersrand basin. Both surface and sub-surface mining was undertaken on the main reef and the main reef leader. The south reef was only mined in part. Gold recovered from the mine amounted to about 10g per ton.

Ferreira's Mine was started by Ignatius Philip Ferreira. A farmer, soldier, speculator and pioneer, Ferreira was born in Grahamstown on 5 July 1840. He joined the great diamond and gold rushes of the 1870s and 1880s to Kimberley, Eastern Transvaal and the Witwatersrand.

In July 1886 Ferreira was camped on the farm Turffontein on the Witwatersrand, near the present-day Johannesburg magistrates' courts, on the road to Kimberley. Other diggers soon joined him and, although he had no official status, he maintained order in the camp. Ferreira's camp grew at an unprecedented rate as rumours of payable gold spread. The camp's importance declined when Randjieslaagte was selected as the centre of the new town, Johannesburg, in October 1886. It's early importance was not, however, forgotten abd part of the present-day suburb, Fereiras Town, occupies the site of the old Ferreira's Camp.

When part of the farm Turffontein was proclaimed on 8 September 1996 Ferreira registered his claims. He finally discovered gold in October 1886. In 1887 the Ferreira Company syndicate was formed, with Ferreira, C Hanau, GH Barber and FH Barber as members. Cornish miners with experience in underground mining were contracted to develop the underground shafts and tunnels.

In May 19887 the Ferreira Gold Mining Company was formed but Ferreira soon lost his share to the Wernher Beit group through adverse circumstances. Ferreira resigned from the board of directors on 3 July 1888.

After the Anglo-Boer War (1899 - 1902) Ferreira settled as a farmer at Kranspoort near Louis Trichard where he died a comparatively poor man.

GOLD

Gold is a dense, soft, shiny, malleable and ductile metal. It is a chemical element with the symbol Au and atomic number 79.

Pure gold has a bright yellow colour and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is atransition metal and a group 11 element. It is one of the least reactive chemical elements solid under standard conditions. The metal therefore occurs often in free elemental (native) form, asnuggets or grains in rocks, in veins and in alluvial deposits. Less commonly, it occurs in minerals as gold compounds, usually with tellurium.

Gold resists attacks by individual acids, but it can be dissolved by the aqua regia (nitro-hydrochloric acid), so named because it dissolves gold. Gold also dissolves in alkaline solutions of cyanide, which have been used in mining. Gold dissolves in mercury, forming amalgam alloys. Gold is insoluble in nitric acid, which dissolves silver and base metals, a property that has long been used to confirm the presence of gold in items, giving rise to the term the acid test.

Gold has been a valuable and highly sought-after precious metal for coinage, jewelry, and other arts since long before the beginning of recorded history. Gold standards have been the most common basis for monetary policies throughout human history, being widely supplanted by fiat currency starting in the 1930s. The last gold certificate and gold coin currencies were issued in the U.S. in 1932. In Europe, most countries left the gold standard with the start of World War I in 1914 and, with huge war debts, failed to return to gold as a medium of exchange.

A total of 165,000 tonnes of gold have been mined in human history, as of 2009. This is roughly equivalent to 5.3 billion troy ounces or, in terms of volume, about 8500 m3, or a cube 20.4 m on a side. The world consumption of new gold produced is about 50% in jewelry, 40% in investments, and 10% in industry.

Besides its widespread monetary and symbolic functions, gold has many practical uses in dentistry, electronics, and other fields. Its high malleability, ductility, resistance to corrosion and most other chemical reactions, and conductivity of electricity led to many uses of gold, including electric wiring, coloured-glass production and even gold leaf eating.

It has been claimed that most of the Earth's gold lies at its core, the metal's high density having made it sink there in the planet's youth. Virtually all of the gold that mankind has discovered is considered to have been deposited later by meteorites which contained the element.

Etymology

The symbol Au is from the Latin: aurum, according to some sources meaning "shining dawn", from Sabine ausum "glowing dawn" although according to definitions within Latin dictionaries the meaning of the word aurum extends only to the same as today's reference to the metal. The disagreement between definitions is possibly due to the accumulation of evidence from archaeology of the original anciency of the metal in civilization; in reference to "the dawn of civilization", and in this respect has become the adopted modern meaning, disassociated from the original etymological Latin.

Characteristics

Gold is the most malleable and ductile of all metals; a single gram can be beaten into a sheet of 1 square meter. Gold leaf can be beaten thin enough to become transparent. The transmitted light appears greenish blue, because gold strongly reflects yellow and red. Such semi-transparent sheets also strongly reflect infrared light, making them useful as infrared (radiant heat) shields in visors of heat-resistant suits, and in sun-visors for spacesuits.

Gold readily creates alloys with many other metals. These alloys can be produced to modify the hardness and other metallurgical properties, to control melting point or to create exotic colours (see below). Gold is a good conductor of heat and electricity and reflects infrared radiation strongly. Chemically, it is unaffected by air, moisture and most corrosive reagents, and is therefore well suited for use in coins and jewelry and as a protective coating on other, more reactive, metals. However, it is not chemically inert. Gold is almost insoluble, but can be dissolved inaqua regia.

Common oxidation states of gold include +1 (gold(I) or aurous compounds) and +3 (gold(III) or auric compounds). Gold ions in solution are readily reduced and precipitated out as gold metal by adding any other metal as the reducing agent. The added metal is oxidized and dissolves allowing the gold to be displaced from solution and be recovered as a solid precipitate.

High quality pure metallic gold is tasteless and scentless, in keeping with its resistance to corrosion (it is metal ions which confer taste to metals).

In addition, gold is very dense, a cubic meter weighing 19,300 kg. By comparison, the density of lead is 11,340 kg/m3, and that of the densest element, osmium, is 22,610 kg/m3.

Colour

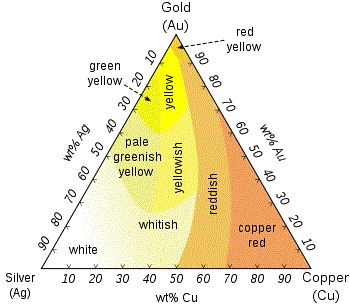

![]()

Whereas most other pure metals are gray or silvery white, gold is yellow. This colour is determined by the density of loosely bound (valence) electrons; those electrons oscillate as a collective "plasma" medium described in terms of aquasiparticle called plasmon. The frequency of these oscillations lies in the ultraviolet range for most metals, but it falls into the visible range for gold due to subtle relativistic effects that affect the orbitals around gold atoms. Similar effects impart a golden hue to metallic caesium (see relativistic quantum chemistry).

Common coloured gold alloys such as rose gold can be created by the addition of various amounts of copper and silver, as indicated in the triangular diagram to the left. Alloys containing palladium or nickel are also important in commercial jewelry as these produce white gold alloys. Less commonly, addition of manganese, aluminium, iron, indium and other elements can produce more unusual colours of gold for various applications.

Jewellery

Because of the softness of pure (24k) gold, it is usually alloyed with base metals for use in jewellry, altering its hardness and ductility, melting point, colour and other properties. Alloys with lower caratage, typically 22k, 18k, 14k or 10k, contain higher percentages of copper, or other base metals or silver or palladium in the alloy. Copper is the most commonly used base metal, yielding a redder colour.

Eighteen-carat gold containing 25% copper is found in antique and Russian jewellery and has a distinct, though not dominant, copper cast, creating rose gold. Fourteen-carat gold-copper alloy is nearly identical in colour to certain bronze alloys, and both may be used to produce police and other badges. Blue gold can be made by alloying with iron and purple gold can be made by alloying with aluminium, although rarely done except in specialized jewellery. Blue gold is more brittle and therefore more difficult to work with when making jewellery.

Fourteen and eighteen carat gold alloys with silver alone appear greenish-yellow and are referred to as green gold. White gold alloys can be made with palladium or nickel. White 18-carat gold containing 17.3% nickel, 5.5% zinc and 2.2% copper is silvery in appearance. Nickel is toxic, however, and its release from nickel white gold is controlled by legislation in Europe.

Alternative white gold alloys are available based on palladium, silver and other white metals, but the palladium alloys are more expensive than those using nickel. High-carat white gold alloys are far more resistant to corrosion than are either pure silver or sterling silver. The Japanese craft of Mokume-gane exploits the colour contrasts between laminated coloured gold alloys to produce decorative wood-grain effects.

Occurrence

The Witwatersrand Basin is a geological formation in the Witwatersrand, South Africa. It holds the world's largest known gold reserves and has produced over 1.5 billion ounces. The basin straddles the old provinces of Transvaal and the Orange Free State and is of the same period as the Vredefort impact of 2.023 Ga ago, and the Bushveld Igneous Complex.

Nearly half of all the gold ever mined has come from the extensive Witwatersrand Basin that was first found near Johannesburg in 1886. The gold occurs in reefs, or thin bands, that are mined at depths of down to 4,000 m - Mponeng gold mine currently being the world's deepest. Although many of the older mines are now nearly exhausted, the Witwatersrand Basin still produces most of South Africa's gold and much of the total world output. Silver and iridium are recovered as gold-refining byproducts, and the basin also has coal mines, although they are bit players in the overall mining of the Basin.

Witwatersrand (meaning 'white water ridge' in Afrikaans) is often called simply "the Rand," and is located in the Gauteng province (formerly a part of Transvaal) of South Africa.

This sedimented cratonic basin covers an elliptical area with a 300 km long major axis from Delmas in the north-east to Theunissen in the south-west, with a small subsidiary basin at Kinross. Dotted outside the basin are older Archaean granites of between 3 and 3.2 Ga, some of which are exposed while others are covered by the much younger Karroo System. The Witwatersrand System is a sequence of shales, quartzites and conglomerates ranging in age from 2.7 Ga for the Hospital Hill subgroup to 2.4 Ga for the Turffontein subgroup. The Lower Witwatersrand is composed mainly of argillaceous clays and shales with occasional banded ironstone, a tillite and an intercalated lava flow, while the Upper Witwatersrand consists almost entirely of quartzites and conglomerates, with its own volcanic horizon.

Gold mines operating in the Witwatersrand Basin

On the East Rand, Ergo is run by DRDGold Limited, a company involved in the extraction of gold and uranium residue from slimes dams and sand dumps on the Central, East and Far East Rand, and to produce sulphuric acid.

On the West Rand, Mponeng, Savuka and TauTona, formerly known as Western Deep Levels, are managed by AngloGold Ashanti, and Kusasalethu (previously Elandsrand) and Doornkop Mines are managed by Harmony Gold. South Deep, Kloof and Driefontein mines are operated by Goldfields and Mintails Limited.

In the Vaal River area, AngloGold Ashanti operate Great Noligwa, Kopanang, Tau Lekoa and Moab Khotsong.

In the Free State Province, Harmony Gold runs Bambanani, Tshepong, Phakisa, Target, Masimong and Joel mines.

Gold's atomic number of 79 makes it one of the higher atomic number elements which occur naturally. Like all elements with atomic numbers larger than iron, gold is thought to have been formed from a supernova nucleosynthesis process. Their explosions scattered metal-containing dusts (including heavy elements like gold) into the region of space in which they later condensed into our solar system and the Earth. Because the Earth was molten when it was just formed, almost all of the gold present on Earth sank into the core. Most of the gold that is present today in the Earth's crust and mantle was delivered to Earth by asteroid impacts during the late heavy bombardment.

On Earth, gold is found in ores in rock formed from the Precambrian time onward. It most often occurs as a native metal, typically in a metal solid solution with silver (i.e. as a gold silver alloy). Such alloys usually have a silver content of 8–10%. Electrum is elemental gold with more than 20% silver. Electrum's colour runs from golden-silvery to silvery, dependent upon the silver content. The more silver, the lower the specific gravity.

Native gold occurs as very small to microscopic particles embedded in rock, often together with quartz or sulfide minerals such as "Fool's Gold", which is a pyrite. These are called lode deposits. The metal in a native state is also found in the form of free flakes, grains or larger nuggets that have been eroded from rocks and end up in alluvial deposits called placer deposits. Such free gold is always richer at the surface of gold-bearing veins owing to the oxidation of accompanying minerals followed by weathering, and washing of the dust into streams and rivers, where it collects and can be welded by water action to form nuggets. Gold sometimes occurs combined withtellurium as the minerals calaverite, krennerite, nagyagite, petzite and sylvanite, and as the rare bismuthide maldonite (Au 2Bi) and antimonide aurostibite (AuSb2). Gold also occurs in rare alloys with copper, lead, and mercury: the minerals auricupride (Cu3Au), novodneprite (AuPb3) and weishanite ((Au, Ag)3Hg2).

Recent research suggests that microbes can sometimes play an important role in forming gold deposits, transporting and precipitating gold to form grains and nuggets that collect in alluvial deposits.

The world's oceans contain gold. Measured concentrations of gold in the Atlantic and Northeast Pacific are 50–150 fmol/L or 10–30 parts per quadrillion (about 10–30 g/km3). In general, gold concentrations for Atlantic and Pacific samples are the same (~50 fmol/L) but less certain. Mediterranean deep waters contain higher concentrations of gold (100–150 fmol/L) attributed to wind-blown dust and/or rivers. At 10 parts per quadrillion the Earth's oceans would hold 15,000 tonnes of gold. These figures are three orders of magnitude less than reported in the literature prior to 1988, indicating contamination problems with the earlier data.

A number of people have claimed to be able to economically recover gold from sea water, but so far they have all been either mistaken or acted in an intentional deception. Prescott Jernegan ran a gold-from-seawater swindle in the United States in the 1890s. A British fraudster ran the same scam in England in the early 1900s. Fritz Haber (the German inventor of the Haber process) did research on the extraction of gold from sea water in an effort to help pay Germany's reparations following World War I. Based on the published values of 2 to 64 ppb of gold in seawater a commercially successful extraction seemed possible. After analysis of 4,000 water samples yielding an average of 0.004 ppb it became clear that the extraction would not be possible and he stopped the project. No commercially viable mechanism for performing gold extraction from sea water has yet been identified. Gold synthesis is not economically viable and is unlikely to become so in the foreseeable future.

Mining

The city of Johannesburg located in South Africa was founded as a result of the Witwatersrand Gold Rush which resulted in the discovery of some of the largest gold deposits the world has ever seen. Gold fields located within the basin in the Free State and Gauteng provinces are extensive in strike and dip requiring some of the world's deepest mines, with the Savuka and TauTona mines being currently the world's deepest gold mine at 3,777 m. The Second Boer War of 1899–1901 between the British Empire and the Afrikaner Boers was at least partly over the rights of miners and possession of the gold wealth in South Africa.

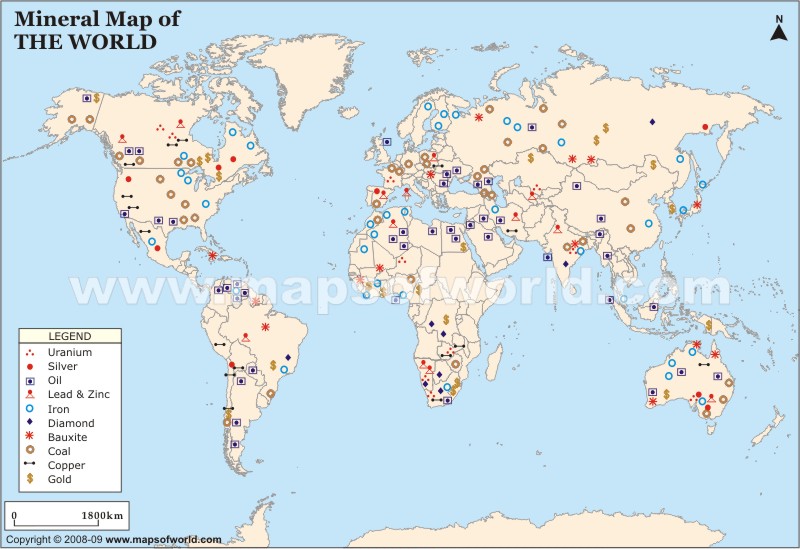

Other major producers are the United States, Australia, Russia and Peru. Mines in South Dakota and Nevada supply two-thirds of gold used in the United States. In South America, the controversial project Pascua Lama aims at exploitation of rich fields in the high mountains of Atacama Desert, at the border between Chile and Argentina. Today about one-quarter of the world gold output is estimated to originate from artisanal or small scale mining.

The process of producing gold and rehabilitation

The process of producing gold

The process of producing gold can be divided into six main phases:

(This basic process applies to both underground and surface operations.)

1 Finding the orebody

AngloGold Ashanti's global exploration programme identifies targets and undertakes exploration, on its own or in conjunction with joint venture partners.

2 Creating access to the orebody

There are two types of mining which take place to access the orebody:

1) Underground – a vertical or decline shaft (designed to transport people and/or materials) is first sunk deep into the ground, after which horizontal development takes place at various levels of the main shaft or decline. This allows for further on-reef development of specific mining areas where the orebody has been identified; and

2) Open-pit – where the top layers of topsoil or rock are removed in a process called 'stripping' to uncover the reef.

3 Removing the ore by mining or breaking the orebody

In underground mining, holes are drilled into the orebody, filled with explosives and then blasted. The blasted 'stopes' or 'faces' are then cleaned and the ore released is now ready to be transported out of the mine.

In open-pit mining, drilling and blasting may also be necessary to release the gold-bearing rock; excavators then load the material onto the ore transport system.

4 Transporting the broken material from the mining face to the plants for treatment

Underground ore is transported by means of vertical and/or horizontal transport systems. Once on surface, conveyor belts usually transport the ore to the treatment plants. Open-pit mines transport ore to the treatment plants in vehicles capable of hauling huge, heavy loads.

5 Services

Mining activities require extensive services, both on the surface and underground, including:

mining engineering services;

mine planning;

ventilation;

provision of consumable resources;

engineering services;

financial, administration and human resource services; and

environmental/permitting services.

6 Processing

Comminution is the breaking up of ore to make gold available for treatment. Conventionally, this process occurs in multi-stage crushing and milling circuits. Modern technology is based on large mills fed directly with run-of-mine material.

Gold ores can typically be classified into: refractory ores, where the gold is locked within a sulphide mineral and not readily available for recovery by the cyanidation process; or free milling, where the gold is readily available for recovery by the cyanidation process.

Refractory ore treatment – after fine grinding, the sulphide materials are floated away from the barren gangue material to produce a high-grade sulphide concentrate. The sulphide concentrate is oxidised by either roasting as at AngloGold Ashanti Mineração or bacterial oxidation (BIOX) as at Obuasi. The oxidation process oxidises the sulphide minerals liberating the gold particles making them amenable to recovery by the cyanidation process.

Free milling and oxidised refractory ores are processed for gold recovery by agitator leaching the ore in an alkaline cyanide leach solution followed generally by adsorption of the gold cyanide complex onto activated carbon-in-pulp (CIP).

The alternative process is the heap-leach process. Generally considered applicable to only high-tonnage, low-grade ore deposits, AngloGold Ashanti has successfully applied this to medium-grade deposits where the ore deposit tonnage cannot economically justify constructing a process plant. Here, the run-of-mine ore is crushed and placed on the leach pad. Low strength alkaline cyanide solution is applied, generally as a drip, to the top of the heap for periods of up to three months. The dissolved gold bearing solution is collected from the base of the heap and transferred to the carbon-in-solution (CIS) columns where the gold cyanide complex is adsorbed onto activated carbon. The stripped solution is recycled back to the top of the heaps.

Gold adsorbed onto activated carbon is recovered by a process of re-dissolving the gold from the activated carbon (elution), followed by precipitation in electro-winning cells and subsequent smelting of that precipitate into doré bars that are shipped to the gold refineries.

The retreatment of tailing stockpile from previous decades' operations is also practised by AngloGold Ashanti. The old tailings are mined by water sluicing followed by agitator leaching in alkaline cyanide solution and recovery of dissolved gold onto activated carbon.

At AngloGold Ashanti operations, the major by-products produced are:

1 - silver, which is associated with gold in ratios ranging from 0.1:1 to 200:1 silver to gold;

2 - sulphuric acid which is produced by scrubbing the gases generated from the roasting plants; and

3 - uranium which is recovered in a process which involves initial acid leaching followed by recovery of the leached uranium onto resin and subsequent stripping with ammonium hydroxide and precipitation of crude yellow cake.

The tailings from the process operations are stored in designated Tailings Storage Facilities designed to enhance water recovery and prevent contaminant seepage into the environment.

Refining

The doré bars, are transported to a refinery for further refining, to as close to pure gold as possible – good delivery status. This gives the assurance that the bar contains the quantity and purity of gold as stamped on the bar.

Rehabilitation

In all the jurisdictions in which the company operates, it is required to conduct closure and rehabilitation activities in order to return the land to a productive state post-mining. Additionally, these same jurisdictions require the company to provide financial assurance, in a form prescribed by law, to cover some, or all of the costs, of the anticipated closure and rehabilitation costs for the operation. Rehabilitation refers to the process of reclaiming mined land to that which existed prior to mining or to a pre-determined use post-mining.

Closure plans are devised prior to the commencement of operation and are regularly reviewed to take into account life-of-mine projections. Although the final cost of closure cannot be fully determined ahead of closure, ample provision is made during the mine's economic operation.

South African Gold Reef Geology

Although there were isolated reports of alluvial gold and some quartz deposits in South Africa as early as 1852 (just after the Clifornian and Australian gold rushes), the real discovery took place in February 1886, when George Harrison found an outcrop of the main reef of gold-bearing conglomerate on Langlaagte Farm near Johannesburg.

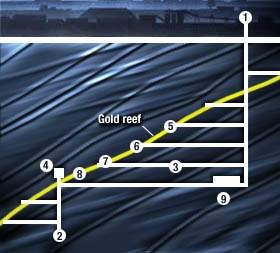

Cutaway of the multi-layered gold bearing reefs of the Witwatersrand

(Credit: courtesy The Chamber of Mines of South Africa)

1

|

Ventersdorp Contract Reef

|

2

|

Mondeor Conglomerate formation

|

3

|

Kimberly Conglomerate formation

|

4

|

Bird Conglomerate formation

|

5

|

Livingstone Conglomerate formation

|

6

|

Johnstone Conglomerate formation

|

7

|

Main Conglomerate formation

|

8

|

Crown Formation

|

9

|

Veldschoen Reef (inner basin reef)

|

10

|

Magnetic Horizon in in lower Jeppestown shale

|

11

|

Buffelsdoorn (Outer Basin reef)

|

12

|

Boulders Reef

|

13

|

Magnetic shale in Witport Jie Formation

|

14

|

Magnetic West Rand shales

|

15

|

Rietfontein tillite

|

The key difference between this field and the earlier Californian and Australian discoveries was that it was not an alluvial deposit which thousands of freelance gold diggers could work, but the tip of low grade reefs which could be mined only at depth and at great initial capital cost.

What outcropped on Langlaagte Farm was one of a crescent of gold reefs around the whole Witwatersrand Basin. These reefs plunge at an angle of 25 degrees or more, sloping inwards towards the centre, to depths of at least 5,000 metres (16,400 feet). Indeed, they have not yet 'bottomed out'.

Cross section of a South African mine (Credit: courtesy The Chamber

of Mines of South Africa)

This gold-bearing conglomerate, usually grading no more than 15g/t (0.48 oz) and often much less, stretches from 65 kms (40 miles) east of Johannesburg to 145 kms (200 miles) west, then swings down south-west to the Orange Free State 320 kms (200 miles) away. Another field, Evander, was found much later 130 kms (80 miles) south-east of Johannesburg, outside the main Witwatersrand system.

The Witwatersrand reefs were deposited between 3,000 and 2,700 million years ago. The reefs vary widely, but the majority are conglomerate, with pebbles of quartz and chert in a matrix of quartz grains, silicate and various sulphides, mainly pyrite. They range from thin, small-pebble reefs, often with great lateral extent, to thick conglomerate.

Many reefs are the product of reworking by fluvial agencies, while others have features compatible with formation on beach-like surfaces in the environment of lakes and seas. They were all formed under shallow water. A large number of different reefs are mined, including the Main Ventersdorp Contact, Kimberley, Carbon Leader and Basal reefs.

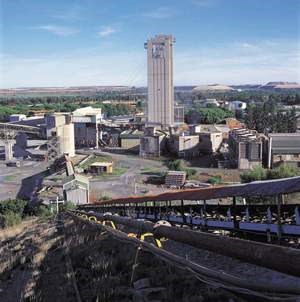

With production of almost one million ounces a year,

Great Noligwa is Anglogold's most productive gold mine.

(Credit: courtesy AngloGold)

The reefs, averaging 20-30 centimetres (7.8-11.8 inches) are extracted from stopes around one metre (3.3 feet) high at planned depths – rather like extracting a thin slice of meat from a sandwich. The narrow stoping widths and mining hard rock reefs at extreme depths have given the South African industry its unique character.

An underground pumping station - an accelerator is added to the

An underground pumping station - an accelerator is added to the

aggregate at this stage before it is pumped out to the work area

(Credit: courtesy AngloGold)

Sources:

http://www.anglogold.co.za

http://www.wikipedia.com

http://info.goldavenue.com

NOTE: Please refer to the following caches in the area that have a Mining theme:

Big Truck

Gold Rhino

Mining Main Street

Some questions to be answered:

1. OPTIONAL: Upload photographs of any items you find important.

2. In front of the Stope, you will find a display cabinet with a rock sample in it. What type of rock is it and what does it consist of? Also describe the colours and the reason therefore?

3. Where, do you think, did the gold come from that is currently mined?

4. Describe the importance of gold deposits in South Africa?

5. What influence did the impact of the Vredefort Meteor had on gold mining in South Africa?